If your workplace was built or refurbished before the 1990s, there is a chance it still contains asbestos floor tiles which may be hidden beneath carpets, vinyl, or laminate. Valued at the time for their strength, heat resistance, and affordability, these tiles are now recognised as potential health hazards.

In this article, we explain what makes asbestos floor tiles dangerous, and how to recognise and manage them safely in line with the Control of Asbestos Regulations 2012.

Are asbestos floor tiles dangerous?

While asbestos floor tiles are classed as low risk when intact, removing them or disturbing the surface is a health risk. When damaged through cutting, sanding, drilling, or wear over time, tiles can release microscopic asbestos fibres into the air.

The invisible nature of asbestos fibres makes them particularly hazardous. They are so small they can remain airborne for hours and cannot be seen, smelled, or tasted, meaning individuals may be unaware of exposure. Once inhaled, the fibres can become lodged in lung tissue.

According to the Health and Safety Executive (HSE), asbestos exposure is responsible for around 5,000 deaths every year in the UK, primarily from mesothelioma, lung cancer, and asbestosis.

Because asbestos-related illnesses have long latency periods, often developing 20 to 50 years after exposure, even brief or low-level exposure can be dangerous if fibres are inhaled repeatedly over time.

When were asbestos floor tiles used?

From the 1950s to the late 1980s, asbestos floor tiles were a popular choice across UK homes, schools, and workplaces for their durability, heat resistance, and affordability. The link between asbestos exposure and serious diseases such as mesothelioma and asbestosis led to strict regulation and a full ban on asbestos use in the UK by 1999.

Well-known products such as Marley floor tiles, vinyl, linoleum and thermoplastic tiles contained chrysotile (white asbestos) to improve strength and flexibility. These tiles were often fixed in place using asbestos-containing adhesives, sometimes referred to as asbestos mastic or asbestos glue.

Many of these tiles remain hidden beneath carpets or newer flooring in buildings constructed before 1990, making safe identification and management essential during any renovation or maintenance work.

How can you tell if floor tiles contain asbestos?

Identifying asbestos in floor tiles can be difficult, as these materials often look very similar to modern vinyl or thermoplastic flooring.

Visual inspection alone is not reliable because asbestos fibres cannot be seen with the naked eye. The only definitive way to confirm whether tiles contain asbestos is through laboratory testing. A competent UKAS-accredited asbestos surveyor can safely take samples of the tile and underlying adhesive and have them analysed under controlled conditions.

If you suspect the presence of asbestos in floor tiles, always stop work immediately and seek professional advice. Proper identification ensures that asbestos floor tile removal or management is carried out in compliance with UK asbestos regulations.

There are several indicators that can help you determine whether your flooring may contain asbestos:

Age of the building and installation date

If your property was built or renovated between the 1950s and the late 1980s, there is a reasonable chance that asbestos floor tiles or asbestos-containing adhesives were used.

Tile size and design

Many asbestos vinyl floor tiles were produced in standard sizes, most commonly 9 x 9 inches (229 x 229 mm). This size was typical of Marley tiles floor and other vinyl floor tiles popular during the 1960s and 1970s. Some later products were also made in 12 x 12 inches or larger, but the 9 x 9 size is a strong indicator of older asbestos-based materials.

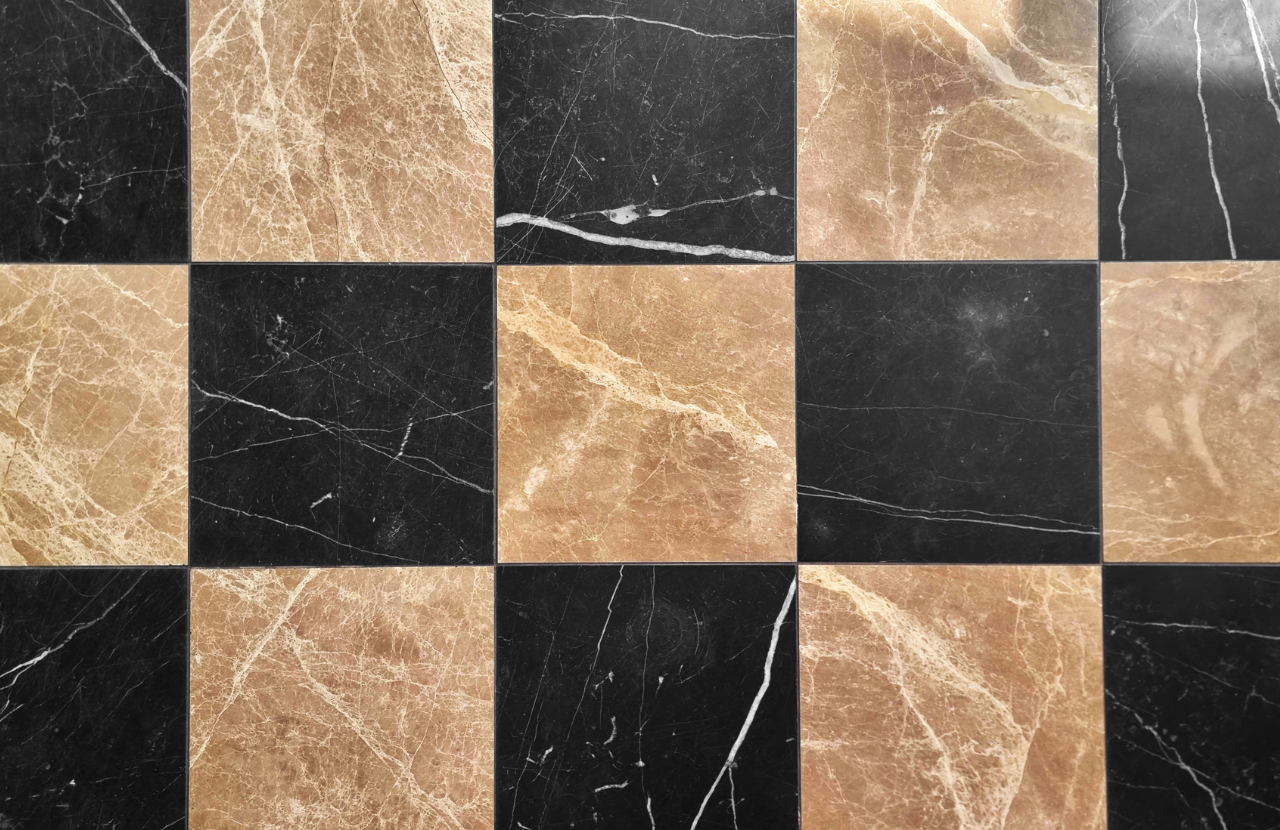

Asbestos tiles often have marbled, mottled, or speckled designs in colours such as brown, grey, red, green, or black, designed to disguise wear and dirt.

Condition and appearance

You may recognise asbestos floor tiles because they appear brittle, cracked, or discoloured, especially if they have been exposed to moisture or heat over time. A dull finish or stiff texture may also suggest thermoplastic composition, which often included asbestos.

Adhesive and backing

Even if the tiles themselves do not contain asbestos, the adhesive (asbestos mastic or asbestos glue) underneath may do. This usually appears as a black, tar-like substance and can release fibres if disturbed.

Some tiles may also have a fibrous or textured backing which indicates that they may contain asbestos.

Asbestos underlay

Asbestos was sometimes used in the underlay beneath thermoplastic or vinyl floor tiles, often as compressed fibreboard or asbestos-backed bitumen paper for insulation and stability.

The underlay is usually fibrous and paper-like with a brittle or flaky texture, or it might look like a dark, tar-like bitumen paper bonded to the subfloor.

Brand and manufacturer names

Certain brand names are particularly associated with asbestos use. Marley floor tiles, for example, frequently contain chrysotile.

Checking product packaging, catalogues, or building records (if available) can provide useful clues.

Location in the building

Asbestos flooring was often installed in high-traffic or utility areas, such as corridors, kitchens, plant rooms, and workshops, where durability and heat resistance were important.

How to manage asbestos flooring in the workplace

Under Regulation 4 of the Control of Asbestos Regulations 2012, employers and duty holders have a legal responsibility to manage the risk of asbestos in non-domestic premises. This includes identifying, recording, and controlling asbestos in flooring tiles and asbestos adhesives.

The objective is not always to have asbestos removed, but to manage it safely so it remains in good condition and undisturbed.

Here are the key duties under Regulation 4:

Identify the location and condition of asbestos in flooring

A management survey should be carried out by a UKAS-accredited asbestos surveyor to identify whether asbestos is present in floor tiles, adhesive, or underlay. The survey results must specify:

- The type and condition of the material (e.g. vinyl, thermoplastic, adhesive)

- The asbestos type (usually chrysotile)

- The location and extent of the asbestos-containing material (ACM)

All findings should be recorded in an asbestos register, which must be kept up to date and made available to anyone likely to disturb the materials, such as maintenance staff or contractors.

Develop and maintain an asbestos management plan

The duty holder must prepare and implement a written asbestos management plan detailing how asbestos flooring will be managed, monitored, and controlled. The plan should include:

- Results from the asbestos survey and register

- Risk assessments for each ACM

- Procedures for monitoring the condition of flooring

- Preventive measures to avoid disturbance

- Emergency procedures in case of accidental damage

The plan must be reviewed regularly, especially after any maintenance, refurbishment, or changes to the condition of the flooring.

For more information, please see our guide, What is an asbestos management plan?

Ensure work is carried out by competent professionals

Any maintenance, encapsulation, or asbestos floor tile removal must be undertaken by trained and competent personnel who understand the risks and comply with HSE-approved methods.

Duty holders should confirm that contractors:

- Have asbestos task-specific training as detailed on the HSE’s website.

- Follow HSE guidance, such as Asbestos Essentials EM9: Removing floor tiles containing asbestos.

- Are competent to determine whether the work is non-licensed or notifiable non-licensed work (NNLW) — that is, whether it involves low-risk material in good condition or damaged material likely to release fibres. If the latter, they must formally notify to the enforcing authority (usually the HSE, or the local authority for offices, shops, and hospitality premises).

Safe management options

If asbestos flooring is in good condition and unlikely to be disturbed, it may be safer to encapsulate, seal, or cover it rather than remove it.

- Encapsulation applies a protective coating to lock in fibres.

- Sealing or covering may involve laying new flooring over the existing tiles, provided the original surface is not damaged during installation.

These approaches must be clearly recorded in the asbestos management plan and inspected periodically to ensure the asbestos remains stable and undisturbed.

Stay safe with UKATA Asbestos Awareness training

If your property may contain asbestos floor tiles, asbestos vinyl flooring, thermoplastic floor tiles, or other asbestos-containing materials, understanding how to recognise and manage them safely is essential.

Our UKATA Asbestos Awareness training helps employers and employees meet the Control of Asbestos Regulations 2012, providing essential knowledge on where asbestos is found, the risks involved, and how to prevent exposure.

Training can be tailored to your organisation, and delivered via eLearning, in a live virtual classroom, or face-to-face at a venue of your choice.

Find out more about our UKATA Asbestos Awareness course or contact our friendly team on 0203 011 4242 / info@praxis42.com

Adam Clarke

Managing Director (Consulting)