In Part 1 of this two-part series, we discussed all the types of asbestos that were once used in the UK and the three types that are most likely to be encountered today.

In this post, we take a closer look at the main three: blue asbestos (crocidolite), brown asbestos (amosite), and white asbestos (chrysotile). By understanding their properties, historical uses, and associated health risks, we can better understand where they might be found today and how to manage them safely.

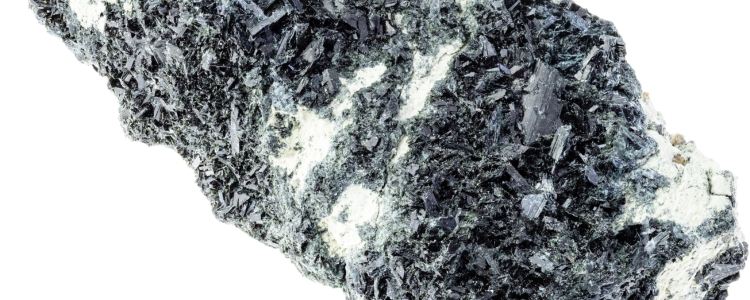

Crocidolite (blue asbestos)

Crocidolite, often referred to as blue asbestos, is part of the amphibole group of asbestos minerals.

Visually, crocidolite asbestos is deep blue to greyish blue in colour. While its striking colour once made it a popular material for certain insulation and cement products, today it is recognised as the most dangerous form of asbestos ever used in the UK.

Why crocidolite is considered the most hazardous

Crocidolite belongs to the amphibole mineral group. It is made up of straight, thin, and rigid needle-like fibres that are easily inhaled deep into the lungs and can pierce lung tissue and pleura (the lining of the lungs).

One of the defining dangers of crocidolite is its bio-persistence. Once inhaled, the fibres do not readily break down or dissolve in the body. Instead, they remain lodged in lung tissue for decades, continually causing inflammation and scarring. This persistence is one of the reasons crocidolite is considered the most potent asbestos type for causing mesothelioma, the aggressive cancer of the lung lining strongly associated with asbestos exposure.

Key properties

The following characteristics made crocidolite asbestos especially valuable in industries where extreme conditions demanded the toughest materials:

Exceptional heat and chemical resistance

Crocidolite was prized for its ability to withstand very high temperatures without degrading, a property that made the mineral ideal for industries where intense heat was common, such as power generation and shipbuilding.

The fibres also resisted strong acids and alkalis far better than other asbestos types, which meant crocidolite could be used safely in chemical plants and laboratory applications.

Outstanding fire protection and thermal insulation

Thanks to a dense structure and high thermal stability, crocidolite offered far greater fireproofing and insulation performance than other asbestos types. This made the mineral a common choice in areas where fire protection was critical, such as pipework, boilers, and steel structures.

Fire resistance was also a key reason crocidolite was incorporated into spray-applied coatings and insulation boards in commercial and industrial buildings.

Common product forms and applications

Crocidolite was frequently supplied in a loose fibre form, making it easy to mix into sprays and insulation pastes. It was also woven into ropes, yarns, and cloths for high-temperature gaskets, seals, and protective equipment.

In addition, crocidolite was used in lagging mixes applied around pipes and vessels, as well as in asbestos cement products.

Unfortunately, the friable nature of many of these applications (especially spray coatings and lagging) means crocidolite is now one of the highest-risk asbestos types encountered during refurbishment or demolition work.

Where blue asbestos was used

Crocidolite saw widespread use in the UK from the 1950s until the mid-1980s, particularly in industries that demanded materials capable of withstanding extreme heat or chemical attack.

Blue asbestos, along with brown asbestos (amosite), was banned in the UK in 1985, following mounting evidence of its extreme health risks. This means that any building constructed before 2000 can still contain asbestos-containing materials (ACMs), which must be managed in accordance with the Control of Asbestos Regulations 2012.

Amosite (brown asbestos)

Amosite (brown asbestos) belongs to the amphibole group of asbestos minerals, the same as crocidolite (blue asbestos).

Amosite is brown to grey, brown in colour. It was mined mainly in South Africa and became one of the most widely used asbestos types in UK construction. Today, it is recognised as one of the most hazardous forms of asbestos, second only to crocidolite in terms of health risks.

Why brown asbestos is considered highly hazardous

As an amphibole, amosite fibres are straight, sharp, and brittle. In amosite these fibres are thicker and less aerodynamic than crocidolite (blue asbestos) fibres which means they are slightly less likely to penetrate the deepest parts of the lungs. However, they are just as dangerous as crocidolite fibres once inhaled.

Another reason amosite is regarded as so hazardous is the friability of many of its common applications. Amosite was frequently used in asbestos insulation board (AIB), sprayed coatings, and lagging, all of which can be easily broken, damaged, or disturbed. When this happens, large volumes of fibres can be released into the air, creating significant exposure risks for anyone nearby.

Key properties

Amosite’s unique characteristics made it particularly attractive to the construction industry, especially where strength, fire safety, and insulation were priorities:

Excellent thermal insulation

Amosite fibres could withstand very high temperatures without breaking down, making them ideal for thermal insulation products. This property meant it was widely used in pipe lagging, boiler insulation, and asbestos insulation boards (AIB), where protecting structures and equipment from heat damage was essential.

Good strength and durability

Amosite fibres are straight, strong, and rigid. When added to boards, panels, and composites, they improved mechanical strength, helping products withstand wear and tear over time.

This toughness was particularly valued in partition walls, soffits, and fire doors, where materials needed both resilience and fire resistance.

Sound absorption

Amosite’s dense, fibrous structure helps absorb sound. This made it popular for ceiling tiles and partition boards in offices, schools, and public buildings, where controlling noise levels was important.

The dual benefits of fire safety and acoustic performance meant amosite became a standard material in many mid-20th-century construction projects.

Where brown asbestos was used

Amosite was heavily used across the UK construction industry from the 1950s until the mid-1980s. Its strength and fire resistance meant it was particularly popular in public buildings, schools, and offices, where asbestos insulating board (AI) and ceiling tiles were standard features.

Amosite together with crocidolite, was banned in the UK in 1985. This means that any building constructed before 2000 may still contain amosite and must be managed under the Control of Asbestos Regulations 2012.

Chrysotile (white asbestos)

White asbestos, or chrysotile, is the only asbestos mineral from the serpentine group of minerals, while brown asbestos (amosite) and blue asbestos (crocidolite) belong to the amphibole group.

Chrysotile is white to greyish in colour and has curly, flexible fibres rather than the straight, rigid fibres of amphiboles. It was mined extensively across Canada, Russia, and other countries and became the most widely used type of asbestos worldwide.

In the UK, chrysotile accounted for most asbestos-containing materials (ACMs) found in homes, schools, and workplaces.

Why white asbestos is considered hazardous

As a serpentine mineral, chrysotile has curly, flexible fibres that are less aerodynamic than the needle-like amphibole fibres of amosite and crocidolite asbestos. This means the fibres are less likely to penetrate as deeply into the lungs. However, once inhaled, they can still lodge in lung tissue and the pleura, causing inflammation, scarring, and cancer.

Although often described as “less dangerous” than amosite and crocidolite, chrysotile is still responsible for asbestos-related deaths worldwide because of its widespread its use. White asbestos was incorporated into thousands of everyday building products, often tightly bound in cement.

When intact and undisturbed, chrysotile cement products are relatively low risk. But when damaged, drilled, or weathered, fibres can be released, exposing workers and building occupants to serious health hazards.

Key properties

Chrysotile’s unique characteristics made it one of the most versatile and widely adopted building materials of the 20th century, used in everything from large-scale construction products to everyday consumer goods.

Flexibility and ease of weaving

Unlike the brittle amphiboles, serpentine fibres are curly, soft, and flexible. This made them easy to spin and weave into textiles, ropes, and gaskets, and particularly valuable in friction products such as brake linings and seals. These qualities meant chrysotile could be manufactured into both heavy-duty industrial textiles and fine woven materials.

Binding strength in composites

Chrysotile fibres bond strongly with cement, forming robust and durable composites. This gave rise to the widespread manufacture of asbestos cement sheets, roofing tiles, gutters, downpipes, and water tanks.

Asbestos cement products became a standard feature of UK construction because they were strong, relatively lightweight, weather-resistant, and affordable.

Fire, heat, and insulation performance

Like all asbestos, chrysotile resists fire and extreme heat. Combined with its adaptability, this made it a common component in roofing products, thermal insulation, floor tiles, and adhesives.

In residential and commercial buildings, chrysotile-based materials offered both fire protection and insulation at low cost, which explains their popularity during the post-war building boom.

Where white asbestos was used

Chrysotile was used across almost every sector of UK construction until the late 1990s and it remains the most common type of asbestos encountered today during building maintenance, refurbishment, or demolition.

White asbestos was finally banned in the UK in 1999, more than a decade after brown and blue asbestos were prohibited in 1985. This means that any building constructed before 2000 may still contain chrysotile and must be managed under the Control of Asbestos Regulations 2012.

Asbestos health risks

Breathing in asbestos fibres can lead to fatal illnesses that can take decades to develop. In Great Britain, asbestos remains the leading cause of work-related deaths. Every year 5,000 people are killed by asbestos, which is greater than the number who die in road accidents. Each week, 20 trades people die from past asbestos exposure.

In 2023, 2,218 people died from mesothelioma, and a similar number of deaths are estimated to result from asbestos-related lung cancer annually.

No type of asbestos is safe. Even short-term or low-level exposure can lead to fatal illnesses, which is why asbestos is strictly regulated under the Control of Asbestos Regulations 2012, and why diligent asbestos management remains essential for any building constructed before the year 2000.

Protect your employees with UKATA Asbestos Awareness Training

Understanding where white, brown and blue asbestos were commonly used is vital for recognising risks that may still exist in older buildings. The Control of Asbestos Regulations 2012 place a clear duty on employers, building owners, and duty holders to manage asbestos safely and prevent exposure.

Approved by the UK Asbestos Training Association (UKATA), our UKATA Asbestos Awareness eLearning course equips employees and managers with the knowledge they need to identify potential asbestos-containing materials, understand the health dangers, and meet their legal obligations.

Find out more on our website or speak to our team today on 0203 011 4242 / info@praxis42.com to discuss training options for your organisation.

Adam Clarke

Managing Director (Consulting)